- This topic is empty.

-

AuthorPosts

-

2025-07-30 at 3:25 pm #4091

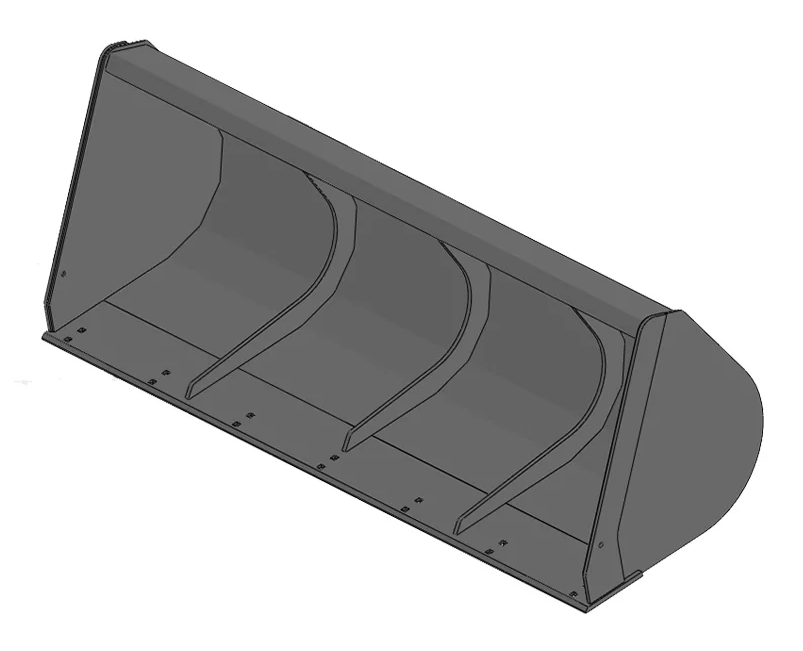

In today’s construction and heavy equipment industries, choosing the right bucket processing service for excavators and loaders is more critical than ever. The bucket is the frontline tool of these machines, and its performance directly affects operational efficiency, equipment lifespan, and jobsite safety. Whether you’re in construction, mining, agriculture, or infrastructure development, selecting a professional, reliable bucket processing partner can significantly improve your bottom line.

Hangzhou Hengli Metal Processing Co., Ltd. stands out as a trusted expert in this field. As a modern enterprise specializing in metal supply chain integration, Hengli provides comprehensive bucket processing services tailored for heavy equipment manufacturers and end-users.

1. Understand Your Equipment and Application Needs

Before selecting a service provider, it’s essential to clearly define your machine type (excavator or loader), operational environment, and performance expectations. Are you using your buckets for high-abrasion work like rock excavation? Or light-duty jobs like soil transport?

Hengli offers custom bucket processing based on these variables. Whether it’s cutting, forming, reinforcing, or welding, the company tailors its approach to match the wear and force requirements of each client’s machinery and industry.

2. Evaluate Processing Capabilities and Technology

High-quality bucket processing requires more than just skilled labor — it demands precision machinery and advanced engineering. Look for providers who use CNC plasma or laser cutting, robotic welding, and automated forming systems to ensure tight tolerances and durability.

At Hengli, advanced technologies such as robotic welding and automated machining centers are applied throughout the bucket processing workflow. From shaping sidewalls to hardfacing cutting edges, each step is optimized for strength, performance, and cost-efficiency.

3. Check for End-to-End Service Offerings

A great bucket processing partner should offer more than just fabrication. Comprehensive services such as bucket repair, rebuild, custom design, surface treatment, and even painting are vital for extending product lifespan and meeting changing field demands.

Hengli provides a full suite of bucket processing services, including:

-

Cutting and bending

-

Welding (manual and robotic)

-

Structural reinforcement

-

Surface protection and coating

-

Final inspection and quality control

They also offer maintenance and repair services, ensuring that your buckets remain in top working condition — an ideal solution for fleet owners looking to extend asset life and reduce replacement costs.

4. Consider Industry Experience and Customization Flexibility

When it comes to bucket processing, industry experience matters. Different sectors — construction, mining, agriculture, or energy — have unique demands for bucket structure, strength, and durability.

With years of experience serving engineering machinery, agricultural equipment, special-purpose vehicles, energy, and automotive components, Hengli understands how to adapt bucket designs to specific use cases. Their engineering team works closely with clients to develop tailored bucket solutions, ensuring that the end product meets both structural and functional requirements.

5. Assess Quality Assurance and After-Sales Support

Reliable bucket processing providers should follow strict quality management systems and offer transparent inspection protocols. This includes weld quality testing, dimensional checks, material traceability, and coating thickness verification.

Hengli is committed to ISO-standard quality management and customer-focused service. Their team ensures every processed bucket passes internal inspection and aligns with client specifications. In addition, their after-sales team is responsive and equipped to support technical questions, urgent maintenance requests, and long-term performance monitoring.

Conclusion: Choose the Right Partner for Long-Term Efficiency

The right bucket processing service for excavators and loaders is not just a vendor — it's a strategic partner that helps you reduce downtime, boost equipment reliability, and improve operational outcomes. Whether you need a custom-built bucket, a quick refurbishment, or a batch of OEM components, the processing quality will shape your productivity.

Hangzhou Hengli Metal Processing Co., Ltd. is proud to be a trusted partner in the heavy equipment supply chain. With strong technical capabilities, complete service systems, and industry-specific experience, Hengli delivers end-to-end bucket processing services that meet the highest standards in performance, durability, and value.

If your business depends on high-quality, long-lasting buckets — especially for excavators and loaders — Hengli is ready to provide solutions that are engineered to perform.

http://www.hlmetal.net

HENGLI -

-

AuthorPosts

- You must be logged in to reply to this topic.