- This topic is empty.

-

AuthorPosts

-

2025-08-01 at 4:21 pm #4103

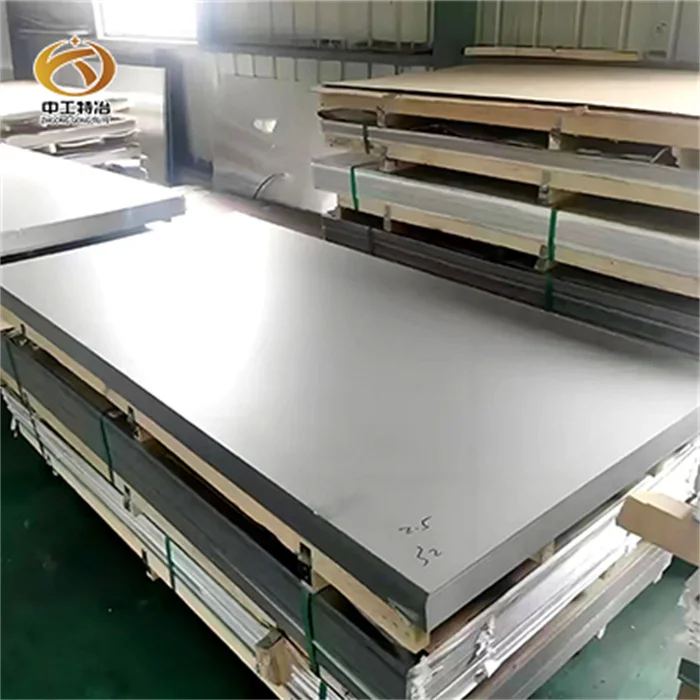

In today's demanding industrial environments, materials are expected to perform reliably under extreme conditions. Among the most widely used and trusted materials across industries is the 304L stainless steel plate. Known for its exceptional corrosion resistance, formability, and strength, 304L stainless steel plate has become a go-to solution for applications ranging from chemical processing and food manufacturing to architectural design and marine structures. In this comprehensive guide, Zhonggongte Metallurgical will dive into the advantages of 304L stainless steel plate. Whether you're an engineer sourcing material for fabrication, a procurement officer comparing metal grades, or a project designer needing reliable structural materials, this article is designed to help you make informed decisions.

What Is 304L Stainless Steel Plate?

The 304L stainless steel plate is a flat-rolled product made from the low-carbon variant of the classic 304 austenitic stainless steel. Designed for high-corrosion resistance and superior weldability, the 304L plate is especially suitable for applications that involve exposure to moisture, acids, alkalis, and heat.

Unlike its high-carbon counterparts, 304L contains less than 0.03% carbon. This small difference plays a huge role in preventing carbide precipitation during welding—making the material ideal for structural assemblies that undergo post-fabrication welding. The plate form is used when greater thickness, rigidity, or structural surface area is required.

Available in thicknesses ranging from 3mm up to 100mm or more, and in widths exceeding 1500mm, 304L stainless steel plate can be customized for pressure vessels, transport equipment, food-grade containers, and more. Its surface finish can be hot rolled (No.1), cold rolled (2B), brushed (No. 4), or mirror-polished (No. 8), depending on the application environment.

Advantages of Using 304L Stainless Steel Plate

The 304L stainless steel plate is one of the most widely used and versatile stainless materials in the world. Its balance of corrosion resistance, mechanical strength, weldability, and hygienic properties makes it suitable for countless applications across industries such as food processing, chemical manufacturing, marine construction, and power generation. Below are the most significant advantages of choosing 304L stainless steel plate for your next project or production line.

Corrosion Resistance

One of the most defining benefits of 304L stainless steel plate is its outstanding corrosion resistance. Composed of approximately 18% chromium and 8% nickel, and with a reduced carbon content compared to standard 304, this alloy offers excellent resistance to a wide range of corrosive agents.

It resists:

-

Oxidizing acids such as nitric acid

-

Mild chlorides, including those found in seawater or coastal atmospheres

-

Industrial solvents, cleaning agents, and food-grade chemicals

This makes 304L stainless steel plate a go-to material for applications in marine environments, chemical tanks, wastewater treatment plants, and beverage production facilities. Its ability to maintain corrosion resistance even after welding or forming ensures long-term durability and reduces the need for costly maintenance or replacement.

Excellent Weldability

The low carbon content (less than 0.03%) of 304L stainless steel plate significantly improves its weldability compared to other stainless steel grades. This means the material is less prone to intergranular corrosion—a common issue in welded joints caused by chromium carbide precipitation at grain boundaries.

With 304L stainless steel plate, fabricators can confidently use:

-

TIG (Tungsten Inert Gas) welding

-

MIG (Metal Inert Gas) welding

-

Plasma arc welding

…without the need for post-weld heat treatment. This results in strong, clean joints that meet structural and sanitary standards while saving time and labor. Industries that rely on complex or continuous welding operations, such as food-grade piping systems, pressure vessels, and pharmaceutical machinery, prefer 304L stainless steel plate for its weld-ready nature.

Superior Formability

Another key advantage of 304L stainless steel plate is its exceptional formability and ductility. It can be sheared, cut, laser-cut, bent, rolled, or stamped with minimal risk of surface cracking or deformation. Its ability to withstand high deformation levels makes it particularly suitable for deep drawing, plate rolling, and enclosure fabrication.

Typical applications that benefit from the formability of 304L stainless steel plate include:

-

Tank linings and walls

-

Sanitary storage vessels

-

Architectural panels

-

Custom cylindrical shells or cones

Whether forming large industrial tanks or small custom components, 304L stainless steel plate retains structural integrity while adapting to complex shapes.

Hygienic Surface

In environments where cleanliness and sterility are non-negotiable, the 304L stainless steel plate excels due to its smooth, non-porous surface. This property prevents the harboring and growth of bacteria, fungi, and other contaminants, which is essential for industries like food and beverage, medical devices, and biotech manufacturing.

Additionally, the plate's easy-to-clean surface complies with strict sanitary standards, including:

-

FDA (U.S. Food and Drug Administration) guidelines

-

EU food contact regulations

-

GMP (Good Manufacturing Practices)

Applications such as commercial kitchens, dairy processing lines, surgical equipment, and pharmaceutical containment areas frequently use 304L stainless steel plate to ensure a hygienic and low-maintenance environment.

Thermal and Oxidation Resistance

The 304L stainless steel plate performs remarkably well under elevated temperatures. It offers oxidation resistance up to 870°C (intermittent exposure) and up to 925°C (continuous service), making it suitable for both low- and high-temperature applications.

This resistance to heat and oxidation makes 304L stainless steel plate ideal for:

-

Automotive exhaust systems

-

Heat exchangers and condensers

-

Furnace components

-

Thermal shields and deflectors

Unlike carbon steel, which scales and weakens when exposed to heat, 304L stainless steel plate retains its mechanical strength, corrosion resistance, and appearance under thermal cycling. As a result, it's frequently used in applications where thermal integrity and long service life are critical.

Whether you are constructing a chemical tank, designing hygienic food processing lines, or fabricating structural components in a coastal facility, the 304L stainless steel plate offers unmatched versatility. It combines corrosion resistance, strength, formability, and easy maintenance into a single material solution. Partnering with a reputable supplier ensures not only high-quality material but also access to value-added services like custom cutting, polishing, and documentation. For long-term performance, reliability, and cost-efficiency, 304L stainless steel plate is the material of choice in industries where durability and quality matter most.

https://www.zhonggongtemetal.com/304-304L-Stainless-Steel-Plate.html

http://www.zhonggongtemetal.com

Jiangsu Zhonggongte Metallurgical Technology Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.