- This topic is empty.

-

AuthorPosts

-

2026-02-05 at 5:00 pm #6249

High-load environments place extreme demands on electrical conductors. Whether in industrial motors, transformers, electric vehicles, or heavy-duty power equipment, conductors must manage mechanical stress, thermal loads, and electrical efficiency simultaneously. In these conditions, material choice directly impacts system reliability, lifespan, and overall performance.

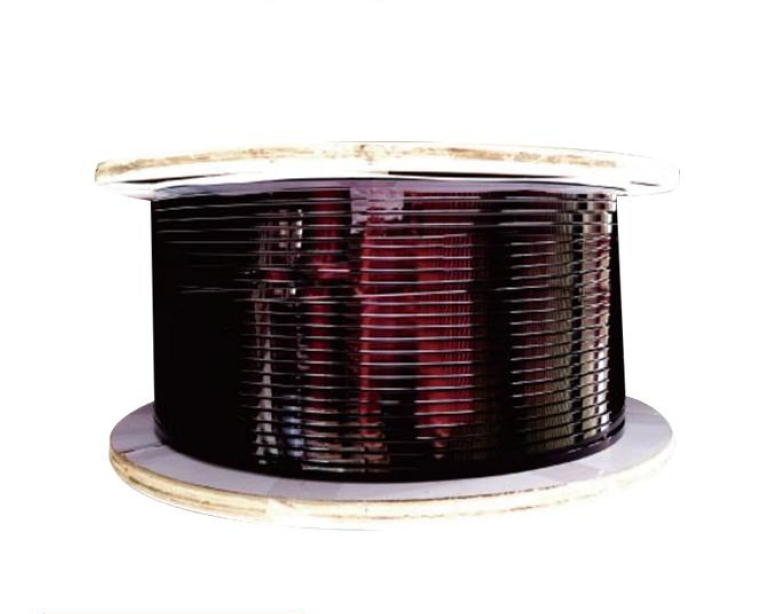

Aluminum flat wire has gained increasing attention as a practical solution for high-load applications. Compared with traditional round conductors, its geometry and material properties offer clear performance advantages when space utilization, heat dissipation, and structural stability matter. At Techsence Wires, aluminum flat wire is developed with these demanding environments in mind, focusing on real operational performance rather than theoretical specifications.

Understanding High-Load Electrical Conditions

High-load environments are characterized by sustained current flow, elevated operating temperatures, and mechanical forces caused by vibration or electromagnetic stress. Common examples include traction motors, industrial generators, large transformers, and high-power converters.

In such applications, conductors must handle continuous electrical loads without excessive heat buildup. At the same time, they must retain dimensional stability to avoid insulation failure, short circuits, or mechanical fatigue. These combined requirements make conductor selection a critical engineering decision.

Why Flat Wire Geometry Matters

One of the defining advantages of aluminum flat wire lies in its shape. Unlike round wire, flat wire offers a larger surface area relative to its cross-section. This increased surface contact improves heat dissipation, allowing thermal energy to escape more efficiently during operation.

In tightly packed windings, flat wire also enables higher slot fill factors. This means more conductive material can be placed within a given space, improving power density without increasing the size of the motor or transformer. For high-load systems where compact design and efficiency are essential, this geometric advantage is significant.

Aluminum as a High-Performance Conductor

Aluminum is often associated with lightweight construction, but its benefits in electrical applications extend far beyond reduced mass. Aluminum flat wire provides an effective balance between conductivity, mechanical flexibility, and thermal performance.

While copper remains a benchmark for conductivity, aluminum offers a favorable conductivity-to-weight ratio. In high-load environments where large conductor volumes are required, reduced weight translates into easier handling, lower structural stress, and improved system efficiency. This is particularly valuable in rotating machinery and mobile applications.

Thermal Performance Under Continuous Load

Thermal management is one of the most critical challenges in high-load electrical systems. Excessive heat accelerates insulation aging, reduces efficiency, and increases the risk of failure.

Aluminum flat wire supports improved thermal performance through both material properties and geometry. The flat profile enhances contact with insulation layers and cooling channels, allowing heat to dissipate more evenly. This reduces localized hotspots that often develop with round conductors under heavy loads.

When paired with high-quality enamel coatings, aluminum flat wire maintains stable performance across extended operating cycles, even in environments with limited airflow or elevated ambient temperatures.

Mechanical Stability and Vibration Resistance

High-load systems are rarely static. Motors and generators experience constant vibration, electromagnetic forces, and mechanical stress. Over time, these forces can deform conductors, leading to insulation damage or winding displacement.

Aluminum flat wire offers improved mechanical stability in winding structures. Its shape allows for tighter stacking and reduced movement within slots, minimizing wear caused by vibration. This structural advantage contributes to longer service life and more consistent electrical performance.

In applications such as traction motors and industrial drives, this resistance to mechanical fatigue is a decisive factor.

Insulation Compatibility and Reliability

Insulation performance is inseparable from conductor performance. Aluminum flat wire is commonly used with advanced enamel coatings designed to withstand thermal cycling, electrical stress, and chemical exposure.

These coatings provide strong adhesion and uniform coverage across the flat surface, reducing the risk of weak points. The result is enhanced dielectric strength and improved resistance to partial discharge, which is critical in high-voltage, high-load environments.

For applications requiring both aluminum and copper solutions, Techsence Wires also offers specialized options such as Aluminum Flat Wire, supporting diverse design requirements while maintaining consistent quality standards.

Space Efficiency in Compact Designs

As industries push toward more compact and efficient equipment, space efficiency has become a major design driver. Aluminum flat wire supports compact winding designs by maximizing conductive material within limited space.

In transformers and motors, this translates into higher output power without increasing core size. For manufacturers, it enables lighter, smaller products without sacrificing performance, which is especially important in electric vehicles, renewable energy systems, and portable industrial equipment.

Long-Term Reliability and Maintenance Benefits

Reliability is not just about initial performance but also long-term stability. Aluminum flat wire contributes to predictable aging behavior when properly designed and manufactured. Its thermal and mechanical characteristics help maintain insulation integrity over time, reducing maintenance requirements and unexpected downtime.

For industrial operators, this reliability translates into lower lifecycle costs, improved operational uptime, and reduced risk of catastrophic failure in critical systems.

Application Scenarios for Aluminum Flat Wire

Aluminum flat wire is widely used across industries that demand high-load performance. Typical applications include high-power electric motors, distribution and power transformers, generators, and energy storage systems. It is also increasingly adopted in electric mobility and renewable energy equipment, where efficiency and weight reduction are essential.

Each application benefits from a tailored approach to conductor design, including precise dimensional control, insulation selection, and quality assurance.

Conclusion

In high-load environments, conductor performance directly affects system efficiency, reliability, and longevity. Aluminum flat wire offers a practical combination of thermal efficiency, mechanical stability, and space optimization that meets the demands of modern electrical equipment.

By focusing on real-world operating conditions and application-driven design, Techsence Wires provides aluminum flat wire solutions that support high-load performance without compromising reliability. For engineers and manufacturers seeking dependable conductors for demanding environments, aluminum flat wire remains a proven and forward-looking choice.

http://www.techsencewire.com

Techsence Wires -

AuthorPosts

- You must be logged in to reply to this topic.