- This topic is empty.

-

AuthorPosts

-

2025-12-30 at 6:11 pm #5748

In the world of modern manufacturing, precision and efficiency are at the core of every production process. As industries evolve and the demand for complex, high-accuracy metal components continues to grow, Electrical Discharge Machining (EDM) has emerged as a vital technology for shaping hard materials with unmatched accuracy.

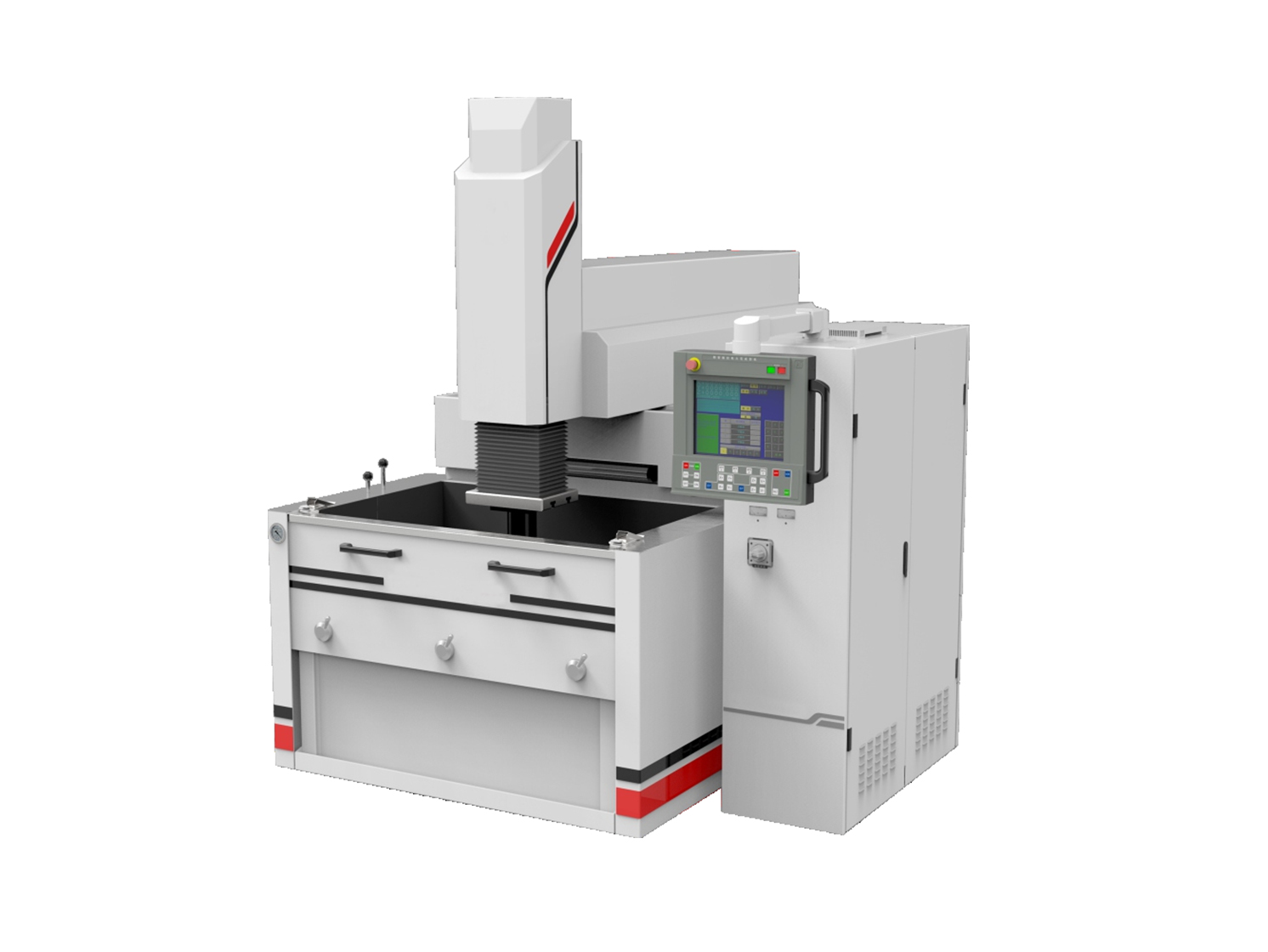

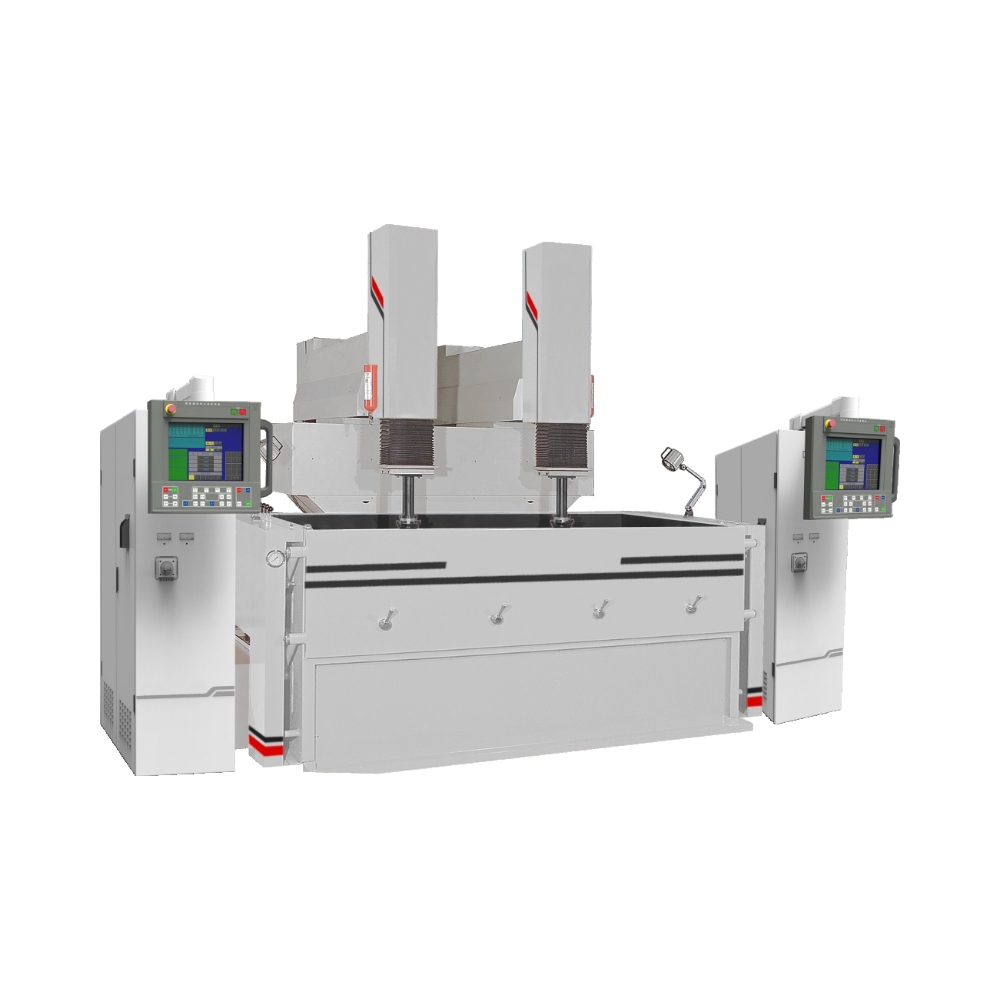

At the forefront of EDM innovation, Suzhou Zhiquan Electromechanical Equipment Co., Ltd. stands as a professional manufacturer and supplier of CNC machining centers, wire-cut EDM machines, EDM spark machines, and milling equipment. With years of experience, advanced technology, and a dedication to quality, the company provides high-performance, reliable, and precision-engineered machining solutions that meet the evolving needs of global metalworking industries.

Understanding Electrical Discharge Machining

Electrical Discharge Machining (EDM) is a non-traditional metal removal process that uses controlled electrical discharges (sparks) to erode material from a workpiece. Unlike conventional cutting methods, EDM can machine extremely hard metals—such as tool steel, tungsten carbide, and titanium—with incredible precision and fine surface finishes.

This process is especially valuable in mold making, aerospace, automotive, and electronics manufacturing, where intricate details and tight tolerances are essential. Suzhou Zhiquan’s EDM machines are built with advanced control systems, stable discharge circuits, and high-speed servo mechanisms, allowing manufacturers to achieve superior results in both productivity and accuracy.

Key Features of Suzhou Zhiquan EDM Solutions

Suzhou Zhiquan Electromechanical Equipment Co., Ltd. designs its EDM machines with a focus on precision, durability, and intelligent performance. Each system integrates state-of-the-art CNC control, high-speed pulse generators, and precision linear guideways to ensure consistent machining quality.

Some of the remarkable features include:

-

High stability and low electrode wear, ensuring longer tool life and smoother finishes.

-

User-friendly interfaces with real-time parameter adjustment for ease of operation.

-

Efficient dielectric circulation systems that improve discharge efficiency and reduce processing time.

-

Compact, ergonomic machine structures designed for optimized workspace utilization.

-

Energy-efficient design with reduced power consumption and minimal maintenance needs.

By combining precision hardware with intelligent software, Suzhou Zhiquan’s EDM solutions offer unmatched machining consistency, speed, and operational reliability, making them ideal for both mass production and custom part fabrication.

Applications Across Precision Metalworking Industries

Electrical Discharge Machining has become indispensable in industries requiring complex shapes and ultra-fine accuracy. In tool and die manufacturing, EDM machines create precise molds and punches for injection molding and stamping processes. In the aerospace and defense sectors, EDM enables the machining of superalloys and heat-resistant metals used in turbine components and engine parts.

For the automotive industry, EDM provides high-quality finishing of gears, shafts, and fuel system components. Meanwhile, in electronics manufacturing, it is essential for producing fine details in micro-components, connectors, and precision molds.

Suzhou Zhiquan’s wire-cut EDM machines and spark EDM systems are widely recognized for their exceptional cutting accuracy, stable performance, and versatile application capabilities, supporting manufacturers in achieving superior product quality and efficiency.

Advantages of Choosing Suzhou Zhiquan Electromechanical Equipment Co., Ltd.

As a professional manufacturer of CNC machining centers, wire-cut EDM machines, spark EDM machines, and milling equipment, Suzhou Zhiquan Electromechanical Equipment Co., Ltd. is committed to delivering comprehensive metalworking solutions that enhance production precision and reliability.

The company’s EDM machines are known for their:

-

High precision machining capability for complex geometries

-

Stable performance and reduced downtime

-

Advanced digital control technology for enhanced process automation

-

Durable mechanical structures ensuring long service life

-

Tailored solutions to meet specific industrial applications

With a strong emphasis on innovation, quality assurance, and customer service, Suzhou Zhiquan has earned a solid reputation among domestic and international clients seeking dependable EDM and CNC machining equipment.

Commitment to Innovation and Quality

Suzhou Zhiquan Electromechanical Equipment Co., Ltd. continually invests in research and development to create next-generation EDM and CNC systems that meet the increasing demands of high-precision manufacturing. Each machine undergoes rigorous quality inspection to ensure optimal accuracy, stability, and performance under real-world production conditions.

The company’s goal is not only to supply machines but also to provide integrated solutions that empower manufacturers to boost productivity, reduce waste, and achieve consistent product excellence.

Conclusion

Electrical Discharge Machining has transformed the precision metalworking industry by enabling manufacturers to achieve results once thought impossible. As a leading manufacturer of CNC machining centers, wire-cut EDM machines, EDM spark machines, and milling equipment, Suzhou Zhiquan Electromechanical Equipment Co., Ltd. delivers innovative, efficient, and durable machining solutions tailored for today’s high-precision industries.

With its unwavering dedication to quality, technology, and customer satisfaction, Suzhou Zhiquan continues to drive progress in precision metalworking—helping industries worldwide achieve excellence in every cut, spark, and detail.

EDM Machines Explained: Key Features, Applications, and Working Principles

http://www.szzhiquan.com

Suzhou Zhiquan Electromechanical Equipment Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.