- This topic is empty.

-

AuthorPosts

-

2025-12-23 at 9:14 am #5650

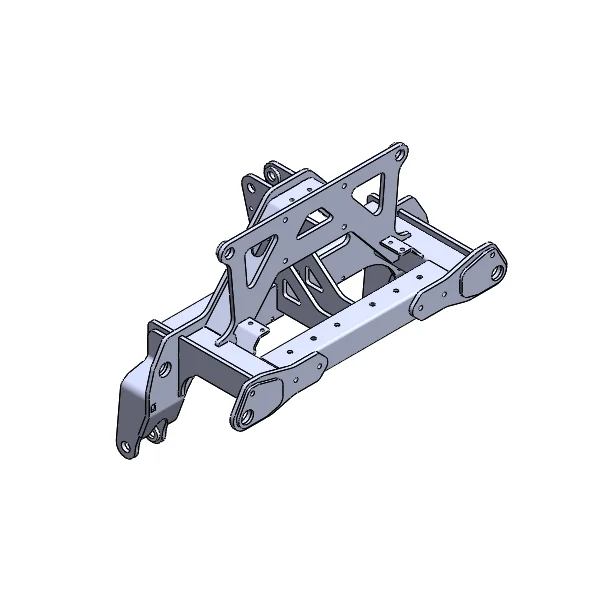

In the demanding world of special vehicle and agricultural equipment manufacturing, precision, durability, and efficiency are critical. Every component, particularly the central frame, must meet exacting standards to ensure the final machinery operates safely and reliably. This is where central frame processing services become indispensable for modern manufacturers.

Ensuring Structural Integrity and Durability

The central frame serves as the backbone of special vehicles and agricultural machinery. A small error in welding, bending, or forming can compromise the entire system, leading to costly failures or safety risks. By utilizing Hengli’s central frame processing services, manufacturers benefit from:

-

Laser, flame, and plasma cutting for precise component shaping

-

CNC machining and robot welding for consistently accurate assembly

-

Bending, forming, and punching that meet exact dimensional requirements

These services ensure that every central frame is robust, durable, and capable of withstanding harsh operational conditions.

Improving Efficiency in Production

Central frame processing is not only about precision but also about optimizing the production workflow. Hengli’s integrated metal supply chain approach enables manufacturers to:

-

Streamline the transition from raw material to finished frame

-

Reduce lead times with automated and digitized processes

-

Minimize human error through robotic and CNC-based operations

This integration ensures that production schedules are met without compromising quality, which is especially important for large-scale agricultural machinery and specialized vehicles.

Supporting Smart Factory Development

Hengli is committed to automation and digitization across the entire industrial chain. Central frame processing fits perfectly into this vision, allowing manufacturers to:

-

Monitor production in real time through digital systems

-

Implement predictive maintenance and quality control

-

Scale operations efficiently without sacrificing precision

By embedding advanced technologies such as robotic welding, CNC machining, and automated inspection into central frame workflows, manufacturers can achieve higher consistency and reduce operational risks.

Why Hengli Is a Trusted Partner

Hengli offers comprehensive services that cover all aspects of central frame processing:

-

Laser cutting, flame cutting, plasma cutting for accurate shaping

-

Bending, forming, punching, welding, robot welding for structural integrity

-

Painting, powder coating, galvanizing for protection and finish

With extensive experience in special vehicles, agricultural machinery, construction equipment, energy, and automotive components, Hengli ensures that every central frame meets stringent quality standards and industry requirements.

Conclusion

In special vehicle and agricultural equipment production, the central frame is critical, and its quality directly impacts the performance and safety of the machinery. By leveraging Hengli’s advanced central frame processing services, manufacturers can achieve superior durability, operational efficiency, and integration into smart factory systems.

http://www.hlmetal.net

Hangzhou Hengli Metal Processing Co.,Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.